Nonwoven fabric is becoming popular and fast replacing plastic since it is more cost-effective and environmentally friendly. Nonwoven manufacturers are constantly working on new designs and types of nonwoven fabrics to meet the demands in the market. Accordingly, suppliers are always on the watch for the best quality nonwoven fabric companies that offer their clients unrivaled products.

This article is dedicated to discussing different types of nonwoven fabrics to help buyers decide when making purchases. It also looks into the applications and properties of nonwoven fabric.

Contents

What Is Nonwoven Fabric?

Nonwoven fabric definition can be a bit complex. However, experts agree that it is a textile structure designed from fibers. These fabric types are typically designed from fiber webs, or continuous filaments strengthened through bonding, gluing, and other methods. In most cases, the techniques used to bond the fiber together include mechanical interlocking, stitch bonding, adhesive bonding, and thermal bonding.

What Are the Different Types of Nonwoven Fabrics?

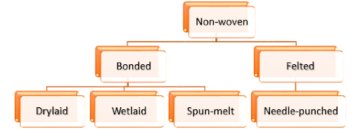

Typically, nonwoven fabric factories are innovative in ensuring they design different types of nonwoven fabric, depending on the properties and materials used.

This means that there are many nonwoven fabric types. However, the four main types of nonwoven fabric include spunbound, airlaid, drylaid, and wetlaid.

Spunbound Nonwoven Fabrics

Spunbound nonwoven fabrics are also known as spunlaced nonwoven fabrics. These types are designed by randomly or uniformly depositing spun, extruded filaments onto a collection belt before bonding the fibers. Air jets or electrostatic charges are used to separate the fibers in the web layering stage.

During the collection stage, the system is perforated to prevent the deflection of the air stream that may result in the uncontrolled carrying of the fibers.

Bonding is used to enhance the strength and integrity of the web. This is usually done by applying heated rolls to the partially heated polymer. Fibers that do not get drawn are always used as thermal binding fibers. In the process, polyethylene is used as low melting bonding points. The process used to make spunbound nonwoven fabric is cost-effective because fabric and fiber productions are combined in one process.

Spunbound nonwoven fabrics are products used in various applications. For instance, they include medical products, such as nonwoven masks, carpet backing, packaging items, and automotive products.

Airlaid Nonwoven Fabrics

Airlaying is one of the nonwoven fabric manufacturing processes. This method is a web forming process in which fiber is dispersed into a fast-moving stream and condensed using a vacuum or high pressure. The material is taken through a bundle of airflow to disperse fibers and bind them on the floating web.

Airlaid nonwoven fabrics are primarily wood pulp with excellent adsorbent properties. The material can be mixed with SAP to enhance the absorption property. This type of nonwoven fabric can also be called dry paper nonwoven fabric.

Airlaid nonwoven fabrics are used in many industries for different applications, such as making cloth lining, embroidery materials, filters, and hygiene products.

Drylaid Nonwoven Fabrics

Drylaid nonwoven fabrics are made of natural or artificial staple fibers. The drylaid nonwoven fabric manufacturing process consists of four steps. The first step involves preparing the staple fibers, followed by opening, mixing, cleaning, and blending. The third phase is carding and then web laying.

Drylaid nonwoven fabrics can be produced in high volumes using different fiber materials, such as synthetic, steel, carbon, and glass. Additionally, they have an isotropic structure. This type of nonwoven fabric is used to make wet wipes, diapers, and filtration products used in breweries.

Wetlaid nonwoven fabrics

Wetlaid nonwoven fabrics are produced through a modified papermaking process. This means that fibers used to make different products are suspended in water first. This type of nonwoven fabric comes with flexible, robust, and textile-fabric properties.

Wetlaid nonwoven fabrics are used in many industries for different applications, including making tea bag papers, face cloths, fiber papers, etc.

Other Types of Nonwoven Fabrics

The four above are just the main types of nonwoven fabrics. However, there are other types: composite nonwoven fabric, melt-blown nonwoven fabric, nanotechnology nonwoven fabric, thermal bonded nonwoven fabric, needle punch nonwoven fabric, and chemically bonded nonwoven fabric, and carded nonwoven fabric.

Properties of Nonwoven Fabrics

Nonwoven fabrics are used in almost every sector to cover a wide array of applications. The main reason for this popularity is because they are highly affordable and environmentally friendly, making them the best alternative to plastic and other non-biodegradable products.

However, nonwoven fabric cannot be used for clothing since the fabric material, and nonwoven fabric manufacturing processes produce lighter products than those made through knitting and weaving. Additionally, this property means the nonwoven fabric cannot be used in applications that require durability.

However, they are perfect for applications that require one-time use products. For example, disposable surgical masks are perfect for such properties.

Applications of Nonwoven Fabrics

As suggested, nonwoven fabrics are used in many fields. They include:

- Nonwoven fabrics are used for making disposable medical gowns

- They are also used to make disposable protective other wears.

- They are used in making nonwoven medical masks and surgical face masks.

Nonwoven fabrics are highly in demand due to the need for coronavirus protective wear such as face masks and sanitized hand wipes. The increasing demand may make some manufacturers produce substandard quality nonwoven products. Therefore, you need to purchase nonwoven fabric from a reputable and top-grade nonwoven fabric supplier.

The choice would be to choose a nonwoven fabric manufacturer who has been in the industry for some time. China nonwoven fabric suppliers offer more affordable and high-quality product lines you can choose from.

The Bottom Line

The development of nonwoven fabric manufacturing processes and technologies has been on the rise. Additionally, manufacturers have become more innovative, designing different types of nonwoven fabrics for various applications globally. The range of nonwoven fabric products currently includes sanitary towels, diapers, wet wipes, medical masks, disposable towels, carpets, filters, etc. These products are recognized internally for their innovative and cost-effective properties. Additionally, nonwoven fabrics are becoming more popular since they are environmentally friendly.

This article has discussed different types of nonwoven fabrics to help you understand them and make a sound buying decision if the need arises.

By Coco Ho

By Coco Ho